JOHANNESBURG (miningweekly.com) – Impala Platinum Refinery and its partners are in the last phase of financial close for the introduction of 8 MW of off-grid electricity from a platinum-catalysed fuel-cell system that will make use of natural gas from the Sasol grid.

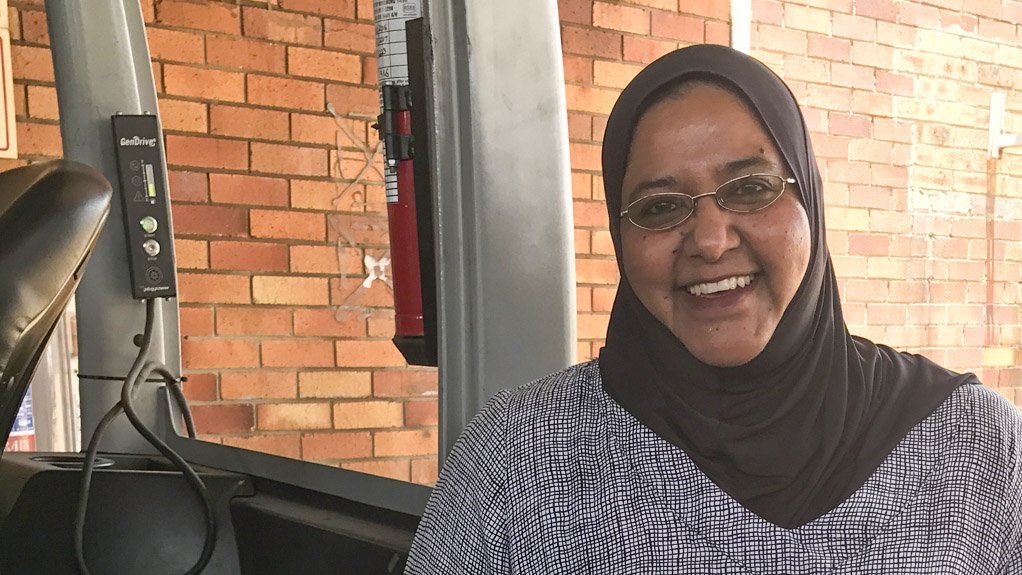

“We expect to get close and first flow of funds by March, with the system being operational by January 2018,” Impala Refining Services (IRS) fuel cell coordinator Fahmida Smith said of the over-the-fence power purchasing agreement (PPA) that the company has clinched.

For the first 20 years, the 8 MW Doosan power plant will belong to the project’s special project vehicle and thereafter ownership will be transferred to Impala.

Speaking to Mining Weekly Online on the eve of Friday’s top-level panel discussion on fuel cells at the Council for Scientific and Industrial Research (CSIR) convention centre in Pretoria, Smith said the company’s heat-integrated fuel-cell plan had been found to be competitive with the Eskom megaflex tariff over the 20-year PPA.

The purpose of the panel discussion is to highlight the benefit that the local manufacture of fuel cells will have on both industrialisation and on the platinum mining sector.

Smith, who will chair the CSIR discussion on the efficacy of emission-free, environment-friendly fuel cells, will have as one of her five panellists Sibanye VP strategic market development Anthea Bath, who expressed great enthusiasm about the learnings achieved during the successful Impala fuel cell project.

“We now have a bankable case. You can hold it up. It’s something real that’s being financed by commercial bankers,” Bath enthused to Mining Weekly Online.

The Doosan system involved has a minimum of 2.5 kg of platinum per 400 kW system, which equates to about 160 000 oz of new platinum demand for every 1 000 MW of fuel-cell power capacity created.

Eric Strayer from Doosan Fuel Cells of the US, who is also one of tomorrow’s CSIR panellists, will talk on the company’s role as an equipment supplier and servicer in the project at the Impala Platinum Refinery, in Springs, as well as Doosan’s localisation plans.

Global analyst Dr Kerry-Anne Adamson of 4th Energy Wave of the UK will provide a directional perspective and point out the gaps that need filling.

Another panellist at tomorrow’s CSIR discussion, Public Investment Corporation (PIC) investments project development head Monique Mathys said on the role PIC could play in fuel-cell development that, as a long-term investor committed to growing the economy through superior investments, PIC would partner with investment opportunities committed to creating a South African fuel-cell ecosystem.

Where the right risk-return balance existed in this sector, PIC would focus on investments linked to strong niche fuel cell market growth and localisation strategies.

“It involves ensuring investment exposure at strategic points along the fuel cell value chain,” Mathys commented to Mining Weekly Online.

FUEL-CELL FORKLIFTS

For the past year, fuel-cell forklifts have been operating without emission and noise within the refinery precinct at Springs.

Their success has prompted a study into the feasibility of developing fuel-cell-driven load haul dumpers (LHDs) for use in underground mining.

The feasibility study will be finalised before Christmas and a LHD prototype request for proposal (RFP) is expected to be invited in January.

The RFPs will be due back by the end of January, development is expected by February and a factory-approved prototype a year later.

Once above-ground mine testing proves successful, underground testing will take place over a 12-month period.

A methanol-water fuelling system is envisaged for the prototype.

An estimated 8 000 oz of platinum will be required for every 1 000 fuel-cell LHDs.

Sibanye is considering how fuel cells might be used within its own business. It makes so much sense from a pure emissions perspective to use fuel-cell equipment underground but a prototype that works is needed first before that can actually happen.

Bath’s view is that South Africa should be supporting and promoting its own fuel-cell applications and own technologies to create demand for platinum.

A collaboration around the fuel-cell forklift took place recently with buy-in from other mining companies to reach commercialisation stage.

“We’re developing a terms of reference to go out to the market to get a professional to do a commercialisation strategy for us,” Smith told Mining Weekly Online.

Terms of reference have also gone out for the development of a special economic zone where fuel-cell manufacture will take place.

Fuel-cell buses are also under consideration within mining-company bus transportation fleets.

The total net present value of the 8 MW project at Implats’ refinery begins at zero and shows its competitiveness over time.

Taking into account the benefits of heat integration, the offsetting of carbon tax and the elimination of diesel generators for back-up power, there is a cost benefit to IRS of installing a fuel-cell system to generate electricity.

In the first part of the project, Impala will pay a premium because of the high cost of capital and the offsetting of the debt funding.

But by the ninth and tenth years, there is a crossover and a major cost-saving trajectory begins.

From the Impala side, a combined heat-and-power application makes economic sense.

The total cost of the project is R720-million, taking stack replacement as well as the debt and equity portions of the investment into account.

The actual capital cost equipment itself is just slightly over R500-million.

EMAIL THIS ARTICLE SAVE THIS ARTICLE

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here